QuadTech to showcase the latest in automation and workflow technologies at CHINA PRINT 2017

Live ColorTrack™ demonstrations to include seven “color management breakthroughs” for packaging printers

Sussex, Wisconsin, USA – 20 April, 2017 – At CHINA PRINT 2017 (May 9-13), QuadTech will present its extensive range of color management, register control, and defect management solutions—designed to ensure consistently high color quality, significantly lower production times, reduced waste and increased profits for printers. Alongside the featured portfolio at the show, visitors to the QuadTech stand (E4-017) will receive live demonstrations including QuadTech’s latest color workflow solution for packaging printers, ColorTrack™, launched at last year’s drupa.

Karl Fritchen, President of QuadTech, comments “CHINA PRINT is one of the leading exhibitions in the print industry and we are excited about participating in this year’s show in Beijing. With printing and converting businesses all over the world continually facing pressure to improve competitiveness and profitability while adding further customer value, the show offers QuadTech the ideal platform to demonstrate how our products enable printers to meet these challenges by taking better control of their print production.”

QuadTech Solutions for Packaging

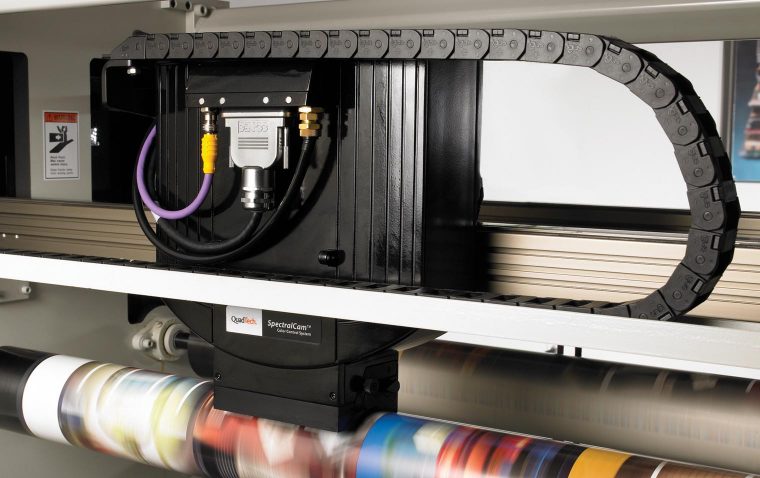

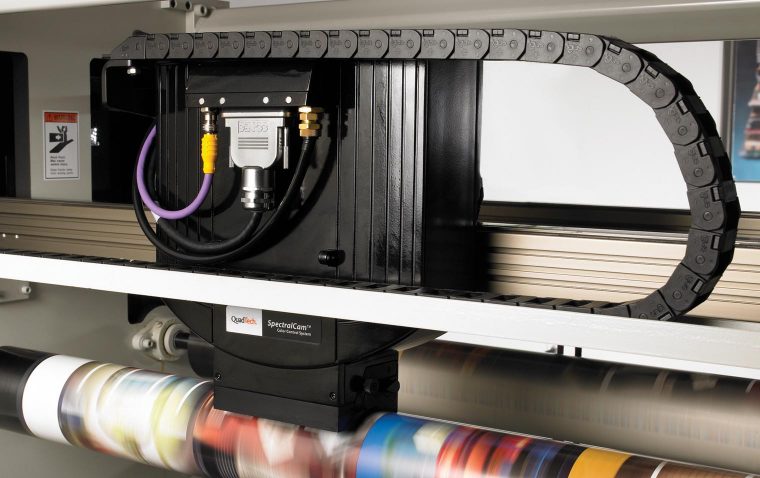

For packaging presses, QuadTech presents Color Measurement with SpectralCam™, an inline system offering exacting color on a variety of substrates. Smart spectrophotometer technology enables the system to quickly detect and analyze colorimetric and density variations from targets located anywhere within the printed product, while the press is running. Maintaining color quality throughout a print run provides new levels of color accuracy and assurance to converters and brand managers that color specifications have been met.

Color Measurement with DeltaCam™, launched at last year’s drupa, makes advanced, inline spectral measurement affordable to individual Packaging print houses. For about half the cost of other inline systems, package printers can utilize accurate, automated L*a*b* measurement on film, paper or board—ensuring that all printed product is within their customers’ color specifications. The M1, M0, ISO compliant technology enables printers to reduce time and waste while confidently maintaining color throughout the roll—without the need to wait for a roll change to measure with a handheld device.

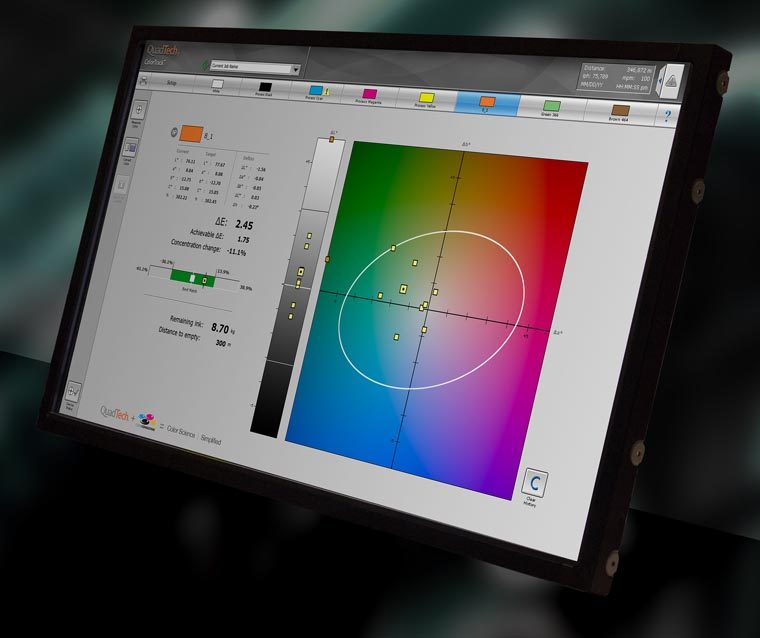

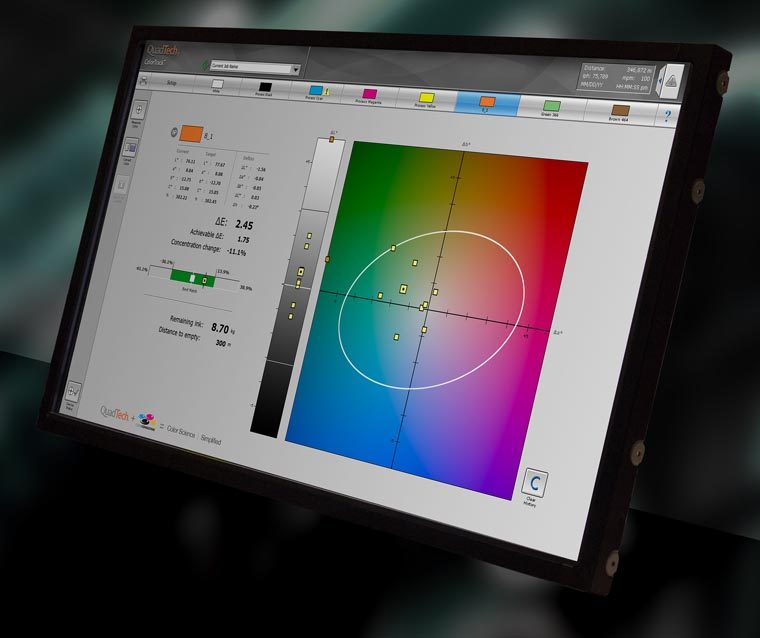

ColorTrack™, a unique new color management software for flexo and gravure packaging applications, is an industry first highly adaptive “color expert in a box” solution for packaging printers. With a variety of options for hand-held and inline configurations, the software facilitates fast, accurate press-side correction of ink formulations. Without any hardware modifications to the press, ColorTrack automates the process of delivering absolute consistency from press-to-press, shift-to-shift, and plant-to-plant.

Seven “Color Management Breathroughs”

According to Wang Zhenhua, QuadTech’s Sales and Operations Manager for China, the live ColorTrack demonstrations will be used to introduce seven “color management breakthrough” technologies. “Our developers and engineers have been very busy since launching ColorTrack last summer,” said Mr. Wang. “We are eager to unveil and explain seven worldwide firsts that we expect to make a very large impact on the industry”:

- Pre-Laminate/Post-Laminate Color Support

- ColorTrack Press-Side Recipe Correction Module

- Ink strength/Anilox Color Correction

- Spot Color Tone Value Calculation to ISO 20654

- Enhanced Color Measurement through Strip Scanning

- Simplified Ink Quantity Tracking via Patented “Virtual Scales”

- Complete, Simplified Workflow

Streamlining Commercial and Newspaper

The QuadTech Color Control System with INSTRUMENT FLIGHT® and SpectralCam™ offers unmatched color control and quality along with the L*a*b*, TVI and density data needed to support color management efforts and monitor adherence to industry standards. The system not only controls solid ink density, but also three-color gray balance and midtone dot gain, ensuring consistent top quality color. The newest feature enables printers to control print production to G7® standards—every day on every print run.

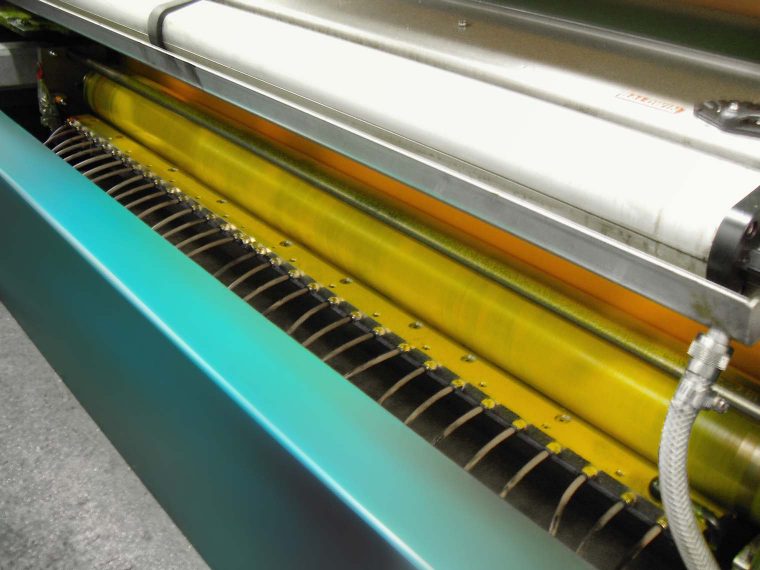

The QuadTech Digital Ink System provides commercial web and newspaper printers a significant quality and cost-saving improvement by providing more accurate ink density control at all press speeds. The system delivers ink savings along with enhanced image quality with precise accuracy. The system is a computer-controlled ink injection solution that replaces traditional open fountains, and can be used to upgrade existing “pump and rail” systems.

Register Guidance with MultiCam® TRIM™ is a highly economical, advanced color-to-color register and cutoff control solution for newspaper printers. Designed for single width, single folder newspaper applications, MultiCam TRIM offers a streamlined set of features for simplified operation, which reliably delivers perfect register for high quality print at a low cost.

About QuadTech, Inc.

QuadTech, Inc. is the world’s leading innovator of advanced color and inspection technology for the printing industry. Founded in 1979, QuadTech sells its automated auxiliary control systems in more than 100 countries to the packaging and converting markets, web offset newspaper and commercial markets, and publication gravure market. Headquartered in Sussex, WI, USA, QuadTech maintains a worldwide network of sales and service operations, and is proud to be registered ISO 9001:2008 DNV.

-

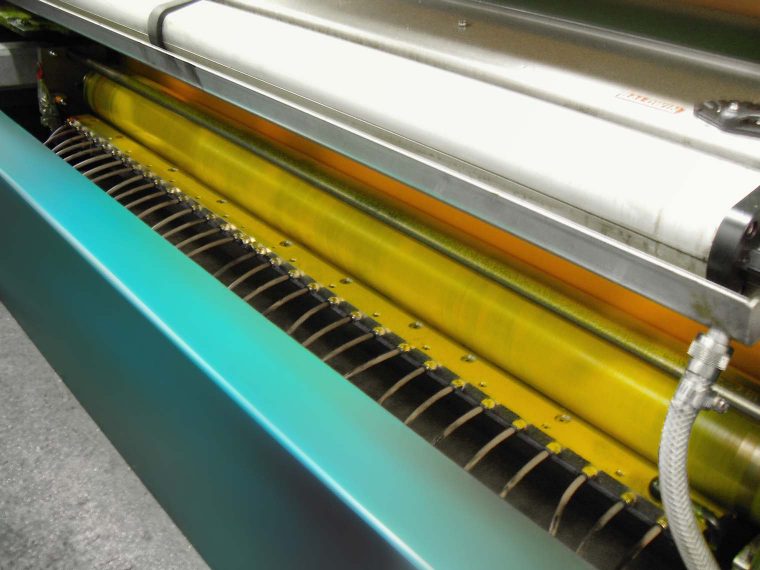

The QuadTech SpectralCam™ delivers L*a*b* data for precise, cost-effective color management.

The QuadTech SpectralCam™ delivers L*a*b* data for precise, cost-effective color management.

Click here to download 300dpi images -

The Digital Ink System replaces fountains with computerized ink injectors, providing precise ink density control across the printed image by metering the correct volume of ink delivered to each control zone.

The Digital Ink System replaces fountains with computerized ink injectors, providing precise ink density control across the printed image by metering the correct volume of ink delivered to each control zone.

Click here to download 300dpi images -

ColorTrack allows press operators to collect and process color measurements, and facilitates fast correction of ink formulations at the press.

ColorTrack allows press operators to collect and process color measurements, and facilitates fast correction of ink formulations at the press.

Click here to download 300dpi images -

QuadTech’s DeltaCam provides accurate inline spectral measurements, reducing waste and ensuring all printed products are within your customers’ color specifications.

QuadTech’s DeltaCam provides accurate inline spectral measurements, reducing waste and ensuring all printed products are within your customers’ color specifications.

Click here to download 300dpi images -

The LED-based MultiCam TRIM camera has the ability to read multiple mark patterns across the web, scanning diamond-shaped marks as small as 0,50 mm.

The LED-based MultiCam TRIM camera has the ability to read multiple mark patterns across the web, scanning diamond-shaped marks as small as 0,50 mm.

Click here to download 300dpi images

QuadTech 将于第九届北京国际印刷技术展览会(以下简称 CHINA PRINT 2017)展示最新自动化与工作流程技术

ColorTrack™ 现场演示将为包装印刷公司介绍七项“色彩管理突破”

美国威斯康星州苏塞克斯 – 2017 年 4 月 20 日 – QuadTech 将在 CHINA PRINT 2017(5 月 9 日至 13 日)上展示一系列色彩管理、套准控制和缺陷管理解决方案,旨在帮助印刷公司持续保持高色彩质量、大幅缩短生产时间、降低浪费并增加利润。除了展会期间展出的特色产品系列,我们还会向来到 QuadTech 展台 (E4-017) 的访客进行现场演示,包括 QuadTech 面向包装印刷公司的最新色彩工作流程解决方案,ColorTrack™,该产品在去年的德鲁巴展会上发布。

QuadTech 总裁 Karl Fritchen 表示,“CHINA PRINT 是印刷行业的一流展会之一,我们很高兴今年能来北京参加展会。”当前,全球印刷和加工行业面临日益增长的压力,我们需要为客户提供更多附加值的同时,来提高竟争力和盈利能力,,因此,展会为 QuadTech 提供了一个理想的平台,展示产品如何帮助印刷公司通过更好地控制印刷产品来迎接这些挑战。”

QuadTech 针对包装提供的解决方案

针对包装印刷,QuadTech 展示了配备 SpectralCam™ 的颜色测量系统,这是一种在线系统,可确保准确测量各种承印物料上颜色的精确性。智能分光光度仪技术使系统能够在线快速检测和分析印刷产品的任何位置发生的颜色色度和密度变化。印刷运行中保持稳定的色彩质量,可提高色彩精度水平,向加工商和品牌管理商确保产品符合色彩规格。

配备 DeltaCam™ 的色彩测量系统 在去年 Drupa 展会上发布,可帮助单个包装印刷厂进行先进的在线光谱测量。只需约其他系统一半的成本,包装印制商便可在薄膜、纸张或板材上自动进行准确的 L*a*b* 测量,确保所有印刷产品符合客户的色彩规格。该技术符合 M1、M0、ISO 标准,可帮助印刷公司缩短生产时间、降低浪费,同时充分保证并记录所有印品的颜色质量,无需等待通过手持仪来逐个测量每卷印品的颜色。更换卷筒便可使用手持设备测量。

ColorTrack™ 是一款全新的用于柔版和凹版包装印刷的颜色管理软件,,是为包装印刷商提供的行业第一个具备高度适应性“一揽子颜色专家”的解决方案。本软件有手持和在线配置不同选项,可在印刷机侧快速、准确地修正油墨配方。ColorTrack 无需更改印刷机硬件,便可实现在不同印刷机、不同班次,不同印刷厂之间保持颜色的绝对一致性的流程自动化。

七项“色彩管理突破”

QuadTech 中国区总经理汪振华先生表示,ColorTrack 的现场展示将介绍七个“色彩管理突破”技术。“我们的开发人员和工程人员从去年夏季发布了 ColorTrack 以来一直致力于该产品的完善和发展。”汪先生说道。“我们期待着向世界公布和展示这七项首创技术,我们相信它会对行业产生深远影响。”

- 层压前/层压后色彩支持

- ColorTrack 印刷机侧配方校正模块

- 油墨强度/网纹辊色彩校正

- 专色色值计算 (ISO 20654)

- 通过带状扫描实现的先进色彩测量

- 通过“虚拟天平”专利技术进行简化的墨量跟踪

- 完整简化的工作流程

简化商业和报纸印刷流程

配备 INSTRUMENT FLIGHT® 和 SpectralCam™ 的 QuadTech 色彩控制系统具备无与伦比的色彩控制能力和色彩质量,可提供所需的 L*a*b*、TVI 和密度数据,以支持色彩管理效果并监控行业标准的依从性。该系统不但能控制实地油墨密度,还能控制三原色灰平衡和中间调网点扩大,确保色彩稳定的一流质量。这一最新功能可帮助印刷公司在日常每次印刷作业中根据 G7® 标准控制印刷生产。

QuadTech 数字油墨系统通过在印刷机全速工作时更精准地控制油墨密度,为商业卷筒印刷和报纸印刷公司提供绝佳的产品质量,大大节约成本。本系统可节约油墨,同时提高图像质量和图像精度。数字油墨系统是一种计算机控制的喷墨解决方案,可取代传统的开放式墨斗墨辊,亦可用于升级现有的“墨泵和墨斗轨”系统。

配备 MultiCam® TRIM™ 的套准引导系统价格非常经济实惠,是适用于报纸印刷公司的高级套色和裁切控制系统。MultiCam TRIM 系统专为单幅、单折页机报纸印刷应用而设计,可提供一套易于操作的简易功能,并且通过完美可靠的套准实现高印刷质量与低成本。

QuadTech, Inc. 简介

QuadTech, Inc. 是全球印刷业高性能色彩与检测技术的创新领导者。QuadTech 成立于 1979 年,为全球 100 多个国家的包装印刷和加工市场、卷筒纸胶印报纸印刷和商业印刷市场及出版物凹版印刷市场提供自动辅助控制系统。QuadTech 总部设在美国威斯康星州的苏塞克斯,拥有遍布全球的销售和售后服务网络。QuadTech 已荣获 ISO 9001:2008 DNV 认证。

-

QuadTech SpectralCam™ 提供 L*a*b* 数据用于精确、符合成本效益的色彩管理。

QuadTech SpectralCam™ 提供 L*a*b* 数据用于精确、符合成本效益的色彩管理。

Click here to download 300dpi images -

数字油墨系统将墨斗替换为计算机控制的注射喷墨器,通过测量为每块控制区域泵送的准确油墨量,可以为整张印刷图像提供精准的油墨密度控制。

数字油墨系统将墨斗替换为计算机控制的注射喷墨器,通过测量为每块控制区域泵送的准确油墨量,可以为整张印刷图像提供精准的油墨密度控制。

Click here to download 300dpi images -

通过 ColorTrack,印刷机操作员可收集和处理色彩测量信息,快速校正印刷机上的油墨配方。

通过 ColorTrack,印刷机操作员可收集和处理色彩测量信息,快速校正印刷机上的油墨配方。

Click here to download 300dpi images -

QuadTech 的 DeltaCam 提供精准的光谱在线测量,降低浪费,确保所有印刷产品符合客户的色彩规格。

QuadTech 的 DeltaCam 提供精准的光谱在线测量,降低浪费,确保所有印刷产品符合客户的色彩规格。

Click here to download 300dpi images -

MultiCam TRIM 摄像头采用 LED,能读取卷筒纸上的多个标识图案,可扫描小至 0.50 毫米的菱形标识。

MultiCam TRIM 摄像头采用 LED,能读取卷筒纸上的多个标识图案,可扫描小至 0.50 毫米的菱形标识。

Click here to download 300dpi images